Roboforming, or robotic sheet metal forming, is an automated manufacturing process that uses industrial robots to bend, stamp, and weld sheet metal into complex 3D parts and assemblies.

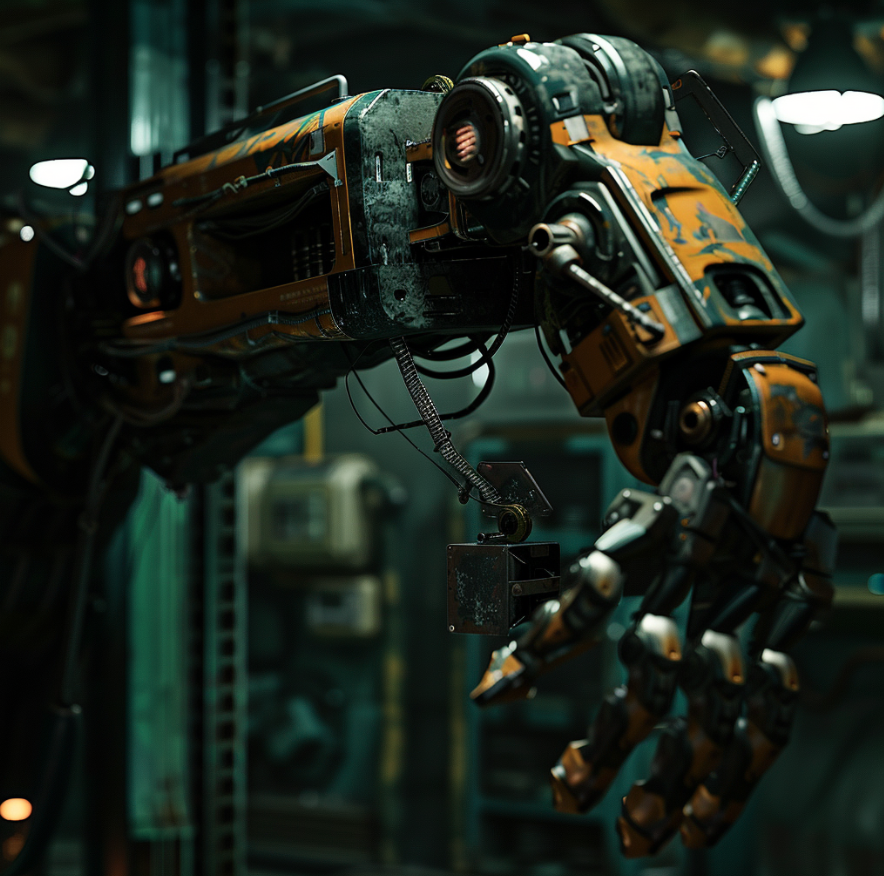

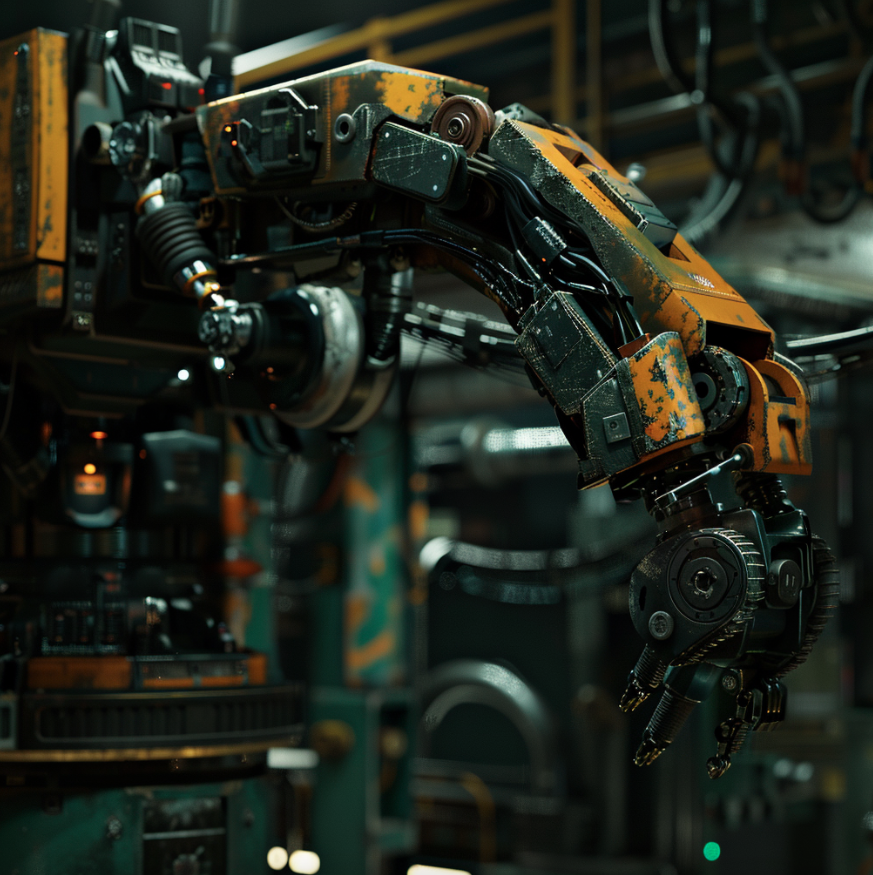

Instead of relying on hard tooling and massive hydraulic presses like traditional sheet metal fabrication, roboforming uses flexible robotic arms with adaptive end-effectors that can manipulate sheet metal in a precise, digitally controlled manner.

The sheet metal is gripped by robotic tools called "end-effectors" and gradually formed into shape. Multiple passes are usually necessary to get the final result.

Roboforming is a relatively new manufacturing technology compared to more traditional manufacturing methods.

Let’s take a look at how they compare:

To understand roboforming, you need to know what makes up a roboforming system.

At its core, a roboforming system consists of three main parts:

Roboforming can significantly improve your manufacturing operations. By automating the forming process, you’ll experience higher productivity and quality.

Roboforming is an exciting new technology, but it does come with some challenges and limitations to be aware of.

Roboforming has many applications across several industries, especially manufacturing. Its flexibility and customization allow for streamlined production of complex parts:

And that's roboforming in a nutshell! This innovative manufacturing method lets you rapidly prototype and produce complex parts with tremendous precision using flexible forming.

While traditional techniques like casting or machining have their place, roboforming opens up new design possibilities and streamlines production.

The key is those highly configurable forming tools that can morph to shape each unique part, and finding the right robot to help you automate.

Ready to transform your production with roboforming? Meet RO1 by Standard Bots, the perfect robot arm for shop floors of all sizes.

Our experts are ready to help you integrate RO1's game-changing capabilities seamlessly into your operations with a 30-day risk-free trial.