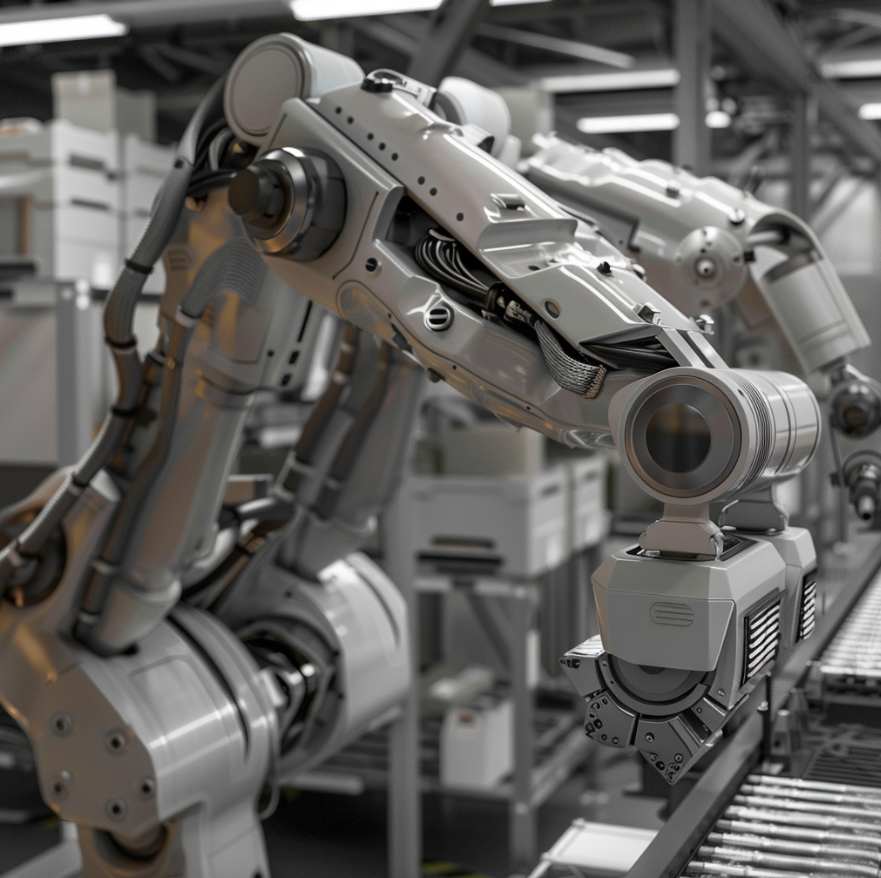

Robotic packing refers to the use of robotic arms and grippers to automatically pick, orient, and place products into packaging at high speeds.

These robotic systems use advanced machine vision and AI to pinpoint the location, orientation, and attributes of objects on a moving conveyor belt. They then pick up the items and place them accordingly.

Robotic packing is often integrated into larger automated packaging lines. Products move down a conveyor where they are detected by vision systems.

Let’s take a look at how these robotic packing solutions work:

Unsurprisingly, these robots are already widely used in the real world.

Here are some industries that are seeing massive gains from robotic packing:

Some of the earliest adopters of robotic packaging were major auto manufacturers. When producing thousands of vehicles per day, efficiency and precision are like oxygen.

Robotic packagers handle tasks like wrapping protective film around car doors and loading packaged components onto pallets for shipping.

For food companies, maintaining freshness and hygiene is priority numero uno. Robotic packagers are perfect in these controlled environments. They can quickly and hygienically place food items into packages, seal and label them, and palletize boxes for distribution.

Many drink companies also use packaging robots to handle bottling, capping, and creating six-packs or cases in their production lines.

The massive volume of products being shipped by e-commerce retailers has fueled greater demand for automated packaging solutions. Packaging robots can pick items from a conveyor belt or shelves, determine the right box size, place the item inside along with any padding or inserts needed, and seal and label the box for shipping.

Some systems even print custom shipping labels and invoices to streamline the workflow. The always-on operation of these robotic packagers allows e-commerce companies to meet tight shipping deadlines, especially during peak periods.

Robotic packing offers several advantages over traditional manual packing methods.

Let’s take a look:

Robotic packing is great, but it’s not perfect.

Let’s take a look at some of the challenges that come with packing robots:

Now you know the basics of robotic packing: What it is, how it works, seeing it in action, the good stuff, and the not-so-good.

While the technology is not perfect yet, it’s evolving and changing by the minute, and it’s rapidly outpacing humans in most (if not all) productivity metrics.

For now, though, it’s exciting to think about what the future may hold!

Transform your robotic packing with RO1 from Standard Bots! It brings the power of automation within reach for businesses of all sizes.

Feel benefits with our 30-day risk-free trial. Our team is here to guide you toward successfully implementing your brand-new RO1.