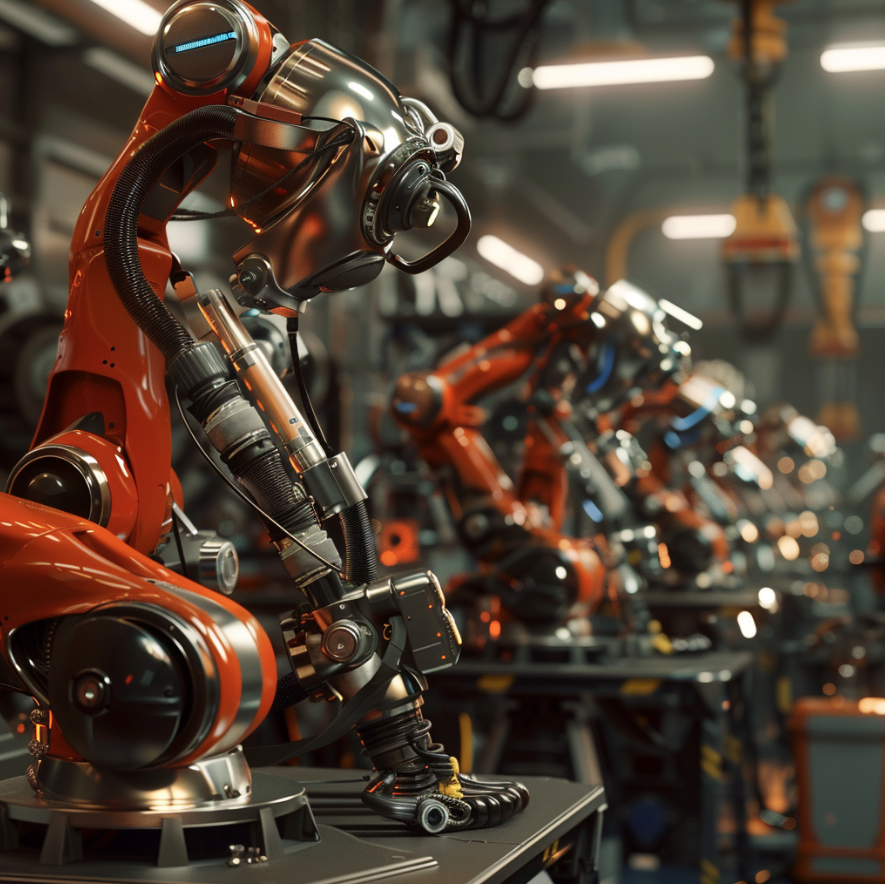

Robotic integrators are companies that help implement robotics systems. They handle everything from designing and planning to installation, programming, and maintenance. In short, they make robotics accessible and help companies reap the benefits.

Robotic integrators don’t just provide the technologies to automate your business processes. They revolutionize how you operate. When you bring on an integrator, you’re making an investment in the future of your company.

Once you’ve decided to work with a robot integrator, you’ll quickly find there are a few hurdles to overcome.

Let’s go in-depth:

Robots need upkeep. Robots reduce some costs but they still need regular maintenance. Make a maintenance plan and budget for repairs to get the most out of your investment.

Finding a high-quality robot integrator isn’t exactly as easy as going into Google and trying the top 3 results.

Here are the rules of thumb you should follow before making a choice:

And that’s the complete rundown on robotic integrators. From understanding what they do and how they work, to the key benefits they provide and the challenges to look out for, you're now equipped with the knowledge to determine if bringing one on is the right move for your business.

The next step is to carefully evaluate potential partners, making sure to assess their experience, capabilities, and cultural fit.

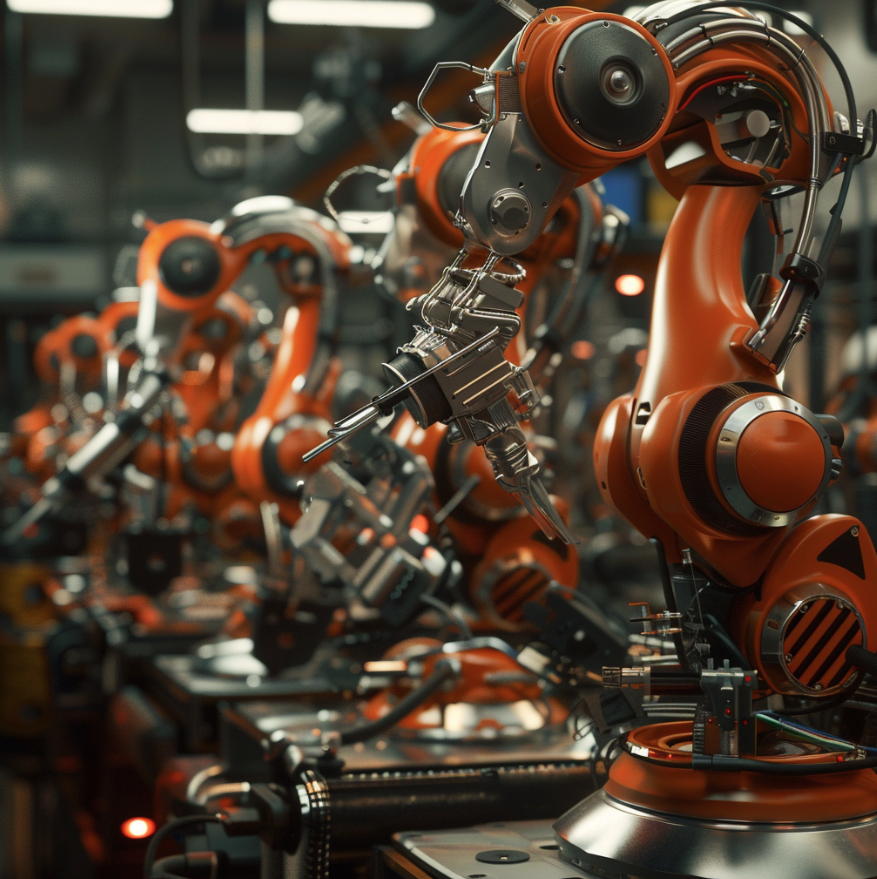

Transform your production with RO1! This innovative robotic arm from Standard Bots brings powerful automation within reach of businesses of every size.

Test-drive the future with our 30-day risk-free trial. See how RO1 revolutionizes your workflow, and our expert team will guide you through every step.