Tools that make robot maintenance easier

Now, that doesn’t mean you’re supposed to do most of this by hand. There are plenty of tools that can help you make it through our checklist without breaking (much of a) sweat.

Let’s check them out:

- Diagnostic software. Diagnostic software is designed specifically for industrial robots and makes troubleshooting issues much more efficient. These programs can run tests to identify problems, provide alerts for potential failures before they happen, and give you a detailed analysis of your robot’s performance and health.

- Remote monitoring. Remote monitoring allows you to keep an eye on your robots from anywhere. Sensors in the robot and connected tools track key metrics like temperature, vibration, load, and speed. The data is uploaded to the cloud where you can monitor performance in real-time and receive alerts if anything is amiss.

- Exoskeletons and lifts. Performing maintenance on industrial robots often requires contorting into uncomfortable positions and handling heavy components like motors, gears, and tools. Exoskeletons and mechanical lifts are designed to reduce strain and make the work easier. Exoskeletons fit over a person’s body to provide arm support and extra strength.

- Augmented reality. Augmented reality (AR) overlays digital information onto the real-world environment. For robot maintenance, AR glasses or headsets can display 3D diagrams, video tutorials, sensor data, and more while you're working on a robot.

- Collaborative robots. These powerful robots often feature built-in safety features. This simplifies maintenance procedures compared to traditional industrial robots with more complex safety protocols.

Common robot maintenance challenges (and how to overcome them)

When it comes to industrial robot maintenance, there are a few common issues that often pop up.

Let’s take a look at them, and how to overcome them:

- Lubrication problems. Robots have many moving parts, like joints and actuators, that require proper lubrication to function smoothly. If lubricants start to break down or dry up, robots can experience friction, noise, overheating, and loss of motion. To prevent this, inspect all lubrication points during routine maintenance and reapply grease or oil as needed according to the manufacturer’s recommendations.

- Loose or damaged wiring. As robots move and manipulate, wiring and cables are prone to becoming loose, frayed, or even severed over time. Look for any visible damage to wiring during inspections and test all connections to ensure signals are being transmitted properly. Make sure to power down the robot completely before performing any wiring repairs or replacement!

- Buildup of dirt and debris. When robots operate in industrial environments, dirt, dust, and other particulates can collect on components like motors, gears, sensors, and tooling attachments. This buildup can impact performance, mobility, and tool changes. Wipe down the entire robot with a damp cloth to remove surface dirt and use compressed air to blow out any debris collected inside joints and motors. For stubborn, caked-on messes, you may need to scrub components manually.

- Faulty or failing components. With frequent use over many hours of operation, some robot parts like motors, controllers, sensors, and tooling can start to malfunction or fail completely. When issues arise that you can’t resolve through basic maintenance, it’s best to contact the robot manufacturer or a certified repair technician to inspect, test, and replace any faulty components.

Summing up

Keeping your babies in 10/10 shape with regular robot maintenance is crucial for maximizing uptime and avoiding costly breakdowns.

So, treat your robot fleet right by sticking to the recommended maintenance intervals, following a checklist, and utilizing specialized tools that make the job easier!

Next steps

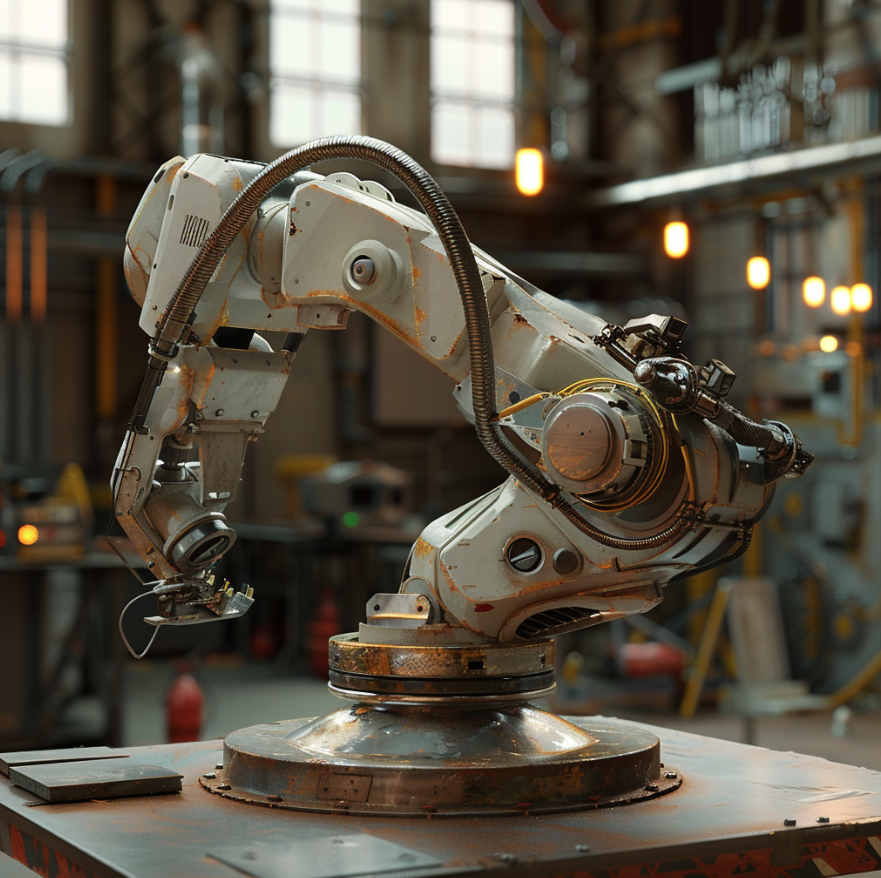

Bring your shop floor to the next level with RO1! This versatile robotic arm from Standard Bots brings the benefits of automation to businesses of every size.

- Get the latest tech at an incredible price: RO1 delivers the features you need for efficient packing, at a cost that makes automation more accessible than ever.

- Powerful and reliable performance: RO1's industrial-grade build tackles demanding workloads (up to 18 kg!) with exceptional speed and precision.

- Designed for a safe and collaborative workspace: State-of-the-art sensors and safety features let you work confidently alongside RO1.

- User-friendly for quick implementation: RO1's no-code interface and advanced AI on par with GPT-4 eliminate the need for complex coding, making setup a breeze.

Experience firsthand how RO1 can revolutionize your packing process with a risk-free 30-day trial. Our expert team is ready to guide you towards success!