Flexible automation explained

Flexible automation refers to automated systems that can easily adapt to changes. These systems are reprogrammable and reconfigurable, allowing them to produce a variety of parts or products. Many modern manufacturing facilities use flexible automation to increase productivity and efficiency.

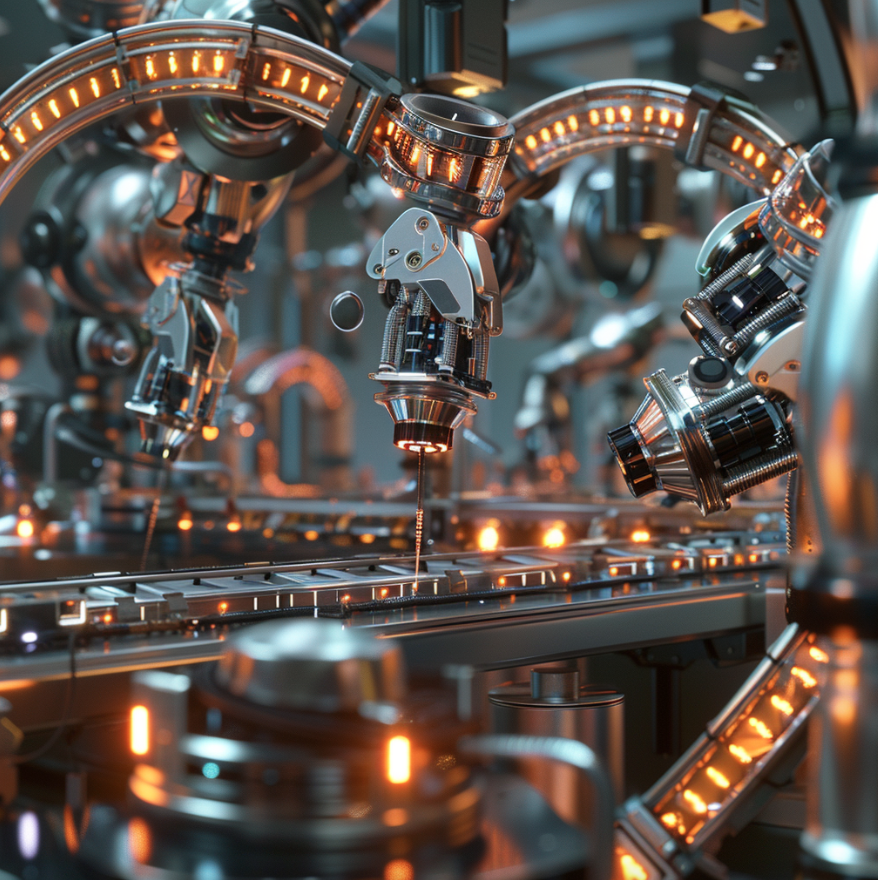

Flexible automation systems combine the benefits of automated and manual manufacturing. Let’s take a look at their typical components:

Flex automation is the norm in many industries to improve efficiency and productivity.

Let’s take a look at some major examples.

Most major car companies use flexible automation in their assembly lines.

Robotic arms are programmed to handle different tasks for installing various components based on the specific vehicle model currently on the line. This allows the factory to produce different models and trims efficiently without needing separate dedicated assembly lines for each product.

Many large warehouses and distribution centers deploy automated storage and retrieval systems that can adapt to the variety of goods being handled.

Robotic lift trucks and conveyor belts are able to transport pallets and packages of different sizes and weights. Automated cranes retrieve goods from tall racks.

These flexible systems allow warehouses to scale and expand their operations to meet increased demands, especially for e-commerce order fulfillment.

Microchip manufacturing and electronics assembly require extremely precise processes.

Flexible automation with reprogrammable robots is ideal for tasks like soldering, component installation, and testing. The systems can be reconfigured to produce different circuit boards and electronic devices with minimal downtime.

Flexible automation offers many benefits over traditional fixed automation.

Not everything is easy in the world of flexible automation systems.

Let’s dive into some challenges:

Flexible automation systems can be complex, but they provide a lot of advantages if implemented correctly.

The most important part is choosing the right mix of fixed and programmable automation tailored to your production needs. So, start small if you're new to flexible automation, focus on quick changeovers, and make training a priority.

The payoff? Just faster production times, lower costs, and the agility to respond to changing market demands. Implementing flexible automation takes work, but the rewards of optimized, versatile manufacturing are worth it.

Flexible automation just got easier with RO1! This versatile robotic arm from Standard Bots is designed to adapt to your changing production needs.

See the benefits firsthand with our 30-day risk-free trial. Experience how RO1 streamlines your workflow, with our team ready to support your success.